|

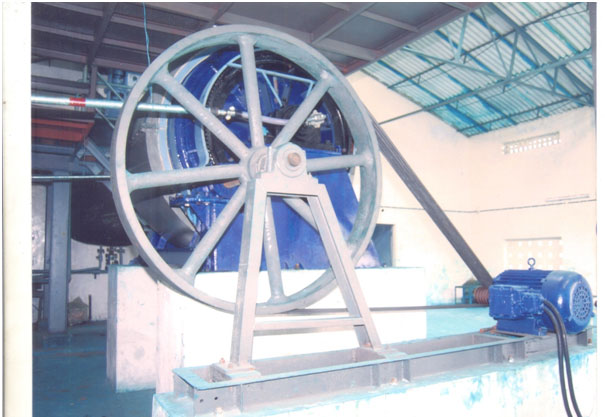

Ball Mill (MS,SS)

Ball Mills are the most used machines for specially dry grinding and also for wet grinding. The shell is made of mild steel with ends welded or bolted to it. Shafts welded and connected to plummer block with bearings allows the complete shell to rotate at a particular RPM. For products like pigments can be easily ground within the shell after running for numerous hours. Products which require no contamination are made in ball mills which are lined with either steatite or alumina lining. The balls used in this machine can be either steatite / alumina / steel balls.Water circulation is given to the jacket for cooling the product. Discharge is done through manhole cover having holes and connected to ball valve.

Most Ideally suited for:

• Hard grinding pigments

• Paints

• Printing Inks

• Minerals

• Allied Chemical Processing Industries

Available in SS and MS with / without Jacket. Also with / without Steatite /Alumina Lining

|